Material Safety considerations for future nanomaterial based Human-Machine Interface equipment and devices to aircrew

Nanomaterials have various extremely interesting properties which could be implemented into devices that could help the aeronautical industry achieve lower aircraft procurement costs, maintenance costs, and fuel consumption. However, despite a steady improvement in the understanding of nanotechnology, the uncertainty on the safety of the use of nanomaterials remains a potential challenge to the adoption of such a technology, especially as studies are showing potential cytotoxicity and genotoxicity of the types of nanomaterials that could be applicable for the industry. One area of concern not fully explored and hence studied in this paper is the potential material risks of nanomaterials to the aircrew in the flight-deck which are deemed to be primarily through devices where there would be physical contact. Overall, the outlook for the integration of nanomaterials in future physical human- machine interfaces in aircraft cockpits indicates that, while hazards exists from the potential cytotoxicity and genotoxicity of such materials, the residual risk to aircrew is low so long as key mitigation requirements for materials safety are considered in the development of future equipment and devices in the flight-deck.

By Leo Jeoh

Introduction

Driven by a general industrial goal to reduce aircraft procurement costs, maintenance costs and fuel consumption, the prospect of technologies that can cut the number of components through multi-functional properties, bring about more durable or self-healing materials, or reduce size and weight of an equipment becomes extremely interesting for the aeronautical sector. On that front, nanotechnology derived materials have shown great promise in areas such as sensors, power sources, nano-electronic devices, electro-magnetic shielding, and potentially structures lighter than today’s composites (Advanced Nanomaterials for Aerospace Applications, 2014). Despite a steady improvement in the understanding of nanotechnology, the uncertainty on the safety of the use of nanomaterials is hard to shake and remains a potential challenge to the adoption of such a technology (Franco, Hansen, Olsen, & Butti, 2007; Asmatulu, 2013).

Such uncertainties are accentuated by results of studies that seem to indicate negative health effects of nanomaterials. For example, graphene, graphene oxide, and reduced graphene oxides have been found to have cytotoxic effects both in vitro and in vivo, although surface modifications may be possible to reduce their toxicity (Guo & Mei, 2014). Such toxicity is believed to occur mainly through free radical formation which then cause damage to biological components through oxidation in organs like the liver and spleen where clearance is slow and hence accumulation is high (hepatotoxicity and splenic toxicity respectively), or organs with high blood flow like the kidneys and lungs (nephrotoxicity and pulmonary toxicity respectively) (Aillon, Xie, El-Gendy, Berkland, & Forrest, 2009). Following similar mechanisms, nanomaterials have also been found to be potentially geno- toxic, interfering with and causing damage to DNA. For example, in vivo studies have found potential genotoxicity from intravenous exposure to amorphous silica nanoparticles, oral exposure to ZnO nanoparticles, and through inhalation of carbon black nanoparticles (Doak & Pfuhler, 2012). Other studies suggest genotoxicity of silver nanoparticles which are becoming more popular in consumer products due to antimicrobial properties (Li et al., 2012). A review conducted by N. Singh et al of several nanomaterial genotoxicity studies indicates that DNA damage could be caused indirectly through the promotion of oxidative stress and inflammatory responses, direct interaction with the DNA by passing through the cellular membrane, or direct contact with DNA during mitosis with sufficient accumulation within a cell (Singh et al., 2009). Health and safety considerations are thus being studied in the aerospace industry; however, such studies typically focus on the impact to personnel involved in the manufacturing or maintenance of nanomaterial infused devices and not so on the aircrew who will be operating such devices on a daily basis. This study thus aims to review the types of devices incorporating nanomaterials that could feature in future cockpits, and their potential hazards to aircrew.

Why HMI Devices as sources for nanomaterial exposure to aircrew

Nanomaterials could be applied to a very wide range of devices in the aircraft, ranging from airframe and components, paints and coatings, engines and engine components, and electrical and electronic equipment (Loeffler, Sutter, Jourdain, & Kristiansen, 2006). However, some these may never have any interaction with the aircrew during normal operations, and thus further precision is necessary to determine the key means through which aircrew could be exposed and absorb nanomaterials.

Not specific to aircrews, general human exposure studies converge that the major exposure routes are inhalation and oral exposure, and that engineered nanomaterials translocate and accumulates in organs and tissue, especially slower-moving organs such as the liver or spleen, when the nanomaterials enter the body’s circulation through the lung, or through gastrointestinal absorption (Boyes, Chen, Chen, & Yokel, 2012; Aschberger, Micheletti, Sokull-Kluttgen, & Christensen, 2011; Savolainen et al., 2010). However, while cytotoxicity and genotoxicity through inhalation or ingestion could be occupational hazards for personnel involved in manufacturing where there is frequent handling of raw nanomaterials, it is generally assumed that such hazards are not likely for end-user consumers like aircrew as the nanomaterial is typically embedded in a matrix material or device (Lowry & Casman, 2009; Lynch & Elder, 2009), or there is a much lower chronic exposure as compared to manufacturing workforces (Singh et al., 2009).

Although inhalation and oral exposure may be less probable events for aircrew, there remains the possibility that nanomaterials could be absorbed directly into the bloodstream through intact skin or open wounds. Dermal uptake could occur through intercellular, intracellular, and follicular penetration through diffusion of the nanomaterials, and several studies have shown the potential of uptakes through such a mechanism (Yokel & MacPhail, 2011). For example, Cd/Se quantum dots with varying surface coatings have been found to penetrate flexed healthy skin (Zhang & Monteiro-Riviere, 2009), and skin penetration of nano-particles leading to accumulation in internal organs have been observed using pig ear skin and hairless mice (Wu et al., 2009). This thus suggests that the primary types of equipment and devices that could pose a potential exposure risk to aircrew during normal operations are those which have some form of physical contact. In a typical cockpit, the function of physical contact between the aircrew and the aircraft is mainly aimed at human-machine interaction (HMI), hence to identify potential hazards of future nanomaterial based equipment and devices, it is deemed that it would suffice to narrow the studies into devices related to HMI in the cockpit.

Future Nanomaterial based cockpit HMI devices

Principally, a pilot’s functions in the cockpit are to aviate, navigate, communicate, and in recent years, to manage systems (Cahill, McDonald, Morrison, & Lynch, 2016). Effective Human-machine Interface from a physical perspective thus relates more to the ergonomics of the cockpit that would ensure the health and productivity of the aircrew to carry out their tasks. The traditional equipment and devices which factor into the ergonomics of the cockpit are thus pilot’s control columns or joysticks (flying control), crew seats, and in recent years, the electronic displays with multi-function re-configurable touch controls (Ionut, 2011). A review of studies being conducted on the future of aircraft cockpits indicate that while there is much work being done in reducing the pilot’s workload through automated systems and software driven interfaces, flying controls, electronic displays, and seats will remain as features in the cockpit (Stanton, Harris, & Starr, 2016; Cahill et al., 2016; Comerford & Johnson, 2007). These features will undoubtedly evolve, and with such evolutions there will be an interest to incorporate nanotechnologies to reap the benefits that this technology could bring about (Vaia, George, Islam, & Dutta, 2012).

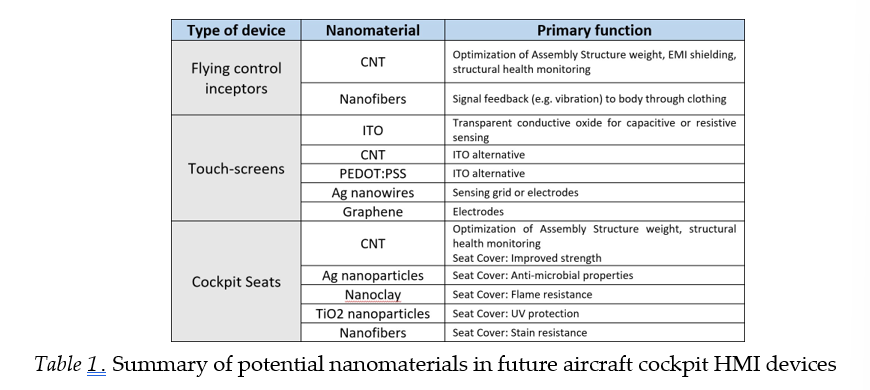

Flying control inceptors may evolve from traditional yokes or collective/cyclic/pedal inceptors in aircraft and helicopters respectively into side-stick controllers (Grunhagen, Mullhauser, Abildgaard, & Lantzsch, 2010; Arbuckle, Abbott, Abbot, & Schutte, 1998), or an enhanced flight control system that provides a pilot with better spatial awareness through vibro-tactile feedback from actuators embedded at specific locations in the pilot’s clothing commensurate with the aircraft’s attitude (Cardin, Vexo, & Thalmann, 2006). While sidestick controllers do not present much weight as compared to other systems, it is feasible that the entire system could incorporate nanomaterials in the future in order to utilize the benefits of strength-to-weight ratio, embedded sensing for structural health monitoring, and incorporated electromagnetic interference shielding and electrostatic dissipation (Nisha & Singh, 2015; Arepalli & Moloney, 2015). Such materials could be based on, though not limited to carbon nanotubes. For vibro-tactile interfaces, these could be enabled in the future through smart textiles with functional nano fibers embedded in the clothing of pilots to sense and provide actuation. The development of multiple bio-medical applications of nanofibers and even piezo-electric nanofibers indicates the potential of such future devices (Stoddard, Steger, Blakney, & Woodrow, 2016; Chang, Dommer, Chang, & Lin, 2012; Xu, Shi, & Kim, 2006).

For electronic displays, the modernization of most aircraft cockpits has led to the integration of touchscreen displays. Touch technology enables easier hand-eye coordination for the aircrew and more software flexibility and space optimization with no extra space required for pointing devices (Barbé, Mollard, & Wolff, 2014). Be it of a capacitive or resistive touch-screen design, the current technology for touchscreens primarily utilizes thin Indium Tin Oxide (ITO) coatings covered by a polymer layer such as Polyethylene Terephthalate (PET), while the future may see touchscreens with lower cost, better reliability, and flexibility using graphene, carbon nano-tubes, silver nano-wires, or high performance PEDOT:PSS transparent conductive films (Coni & Rouzes, 2014; Kim et al., 2015; Jo et al., 2012; Lubianez, 2011). Further developments of electronic displays may also include vibro-tactile stimulators in a data glove that would be part of a Virtual Reality based cockpit (Comerford & Johnson, 2007) and thus introduce nanofiber based devices like those already discussed for flight control inceptors.

Aircraft cockpit seats have fundamentally maintained its function of providing ergonomics and improvement of crash-survivability to the pilot’s throughout the years of aircraft development. Being an assembly that requires a certain mechanical strength, the optimization of the seat structure through nanomaterials such as carbon-nanotubes could be reasonably forseen in the future. Further improvements may be through the incorporation of nanomaterials to the aircraft seat covers in order to provide anti-microbial, fire resistance, stain resistance, improved aesthetics, strength and wear resistance, UV protection, or other peripheral enhancements like fragrance release. Such properties would require the introduction of silver nano-particles, intumescent or nano-clay coatings, carbon nanotubes, superhydrophobic polymer nanofilaments, and titanium dioxide nanoparticles (Haydon, 2012).

Overall, aircrew of future aircraft cockpits may find themselves working in a flight-deck with an increasing amount of nanomaterials embedded within the devices that they have to interact with during normal operations. The potential nanomaterials as discussed above are summarized in Table 1.

Materials Safety Assessment

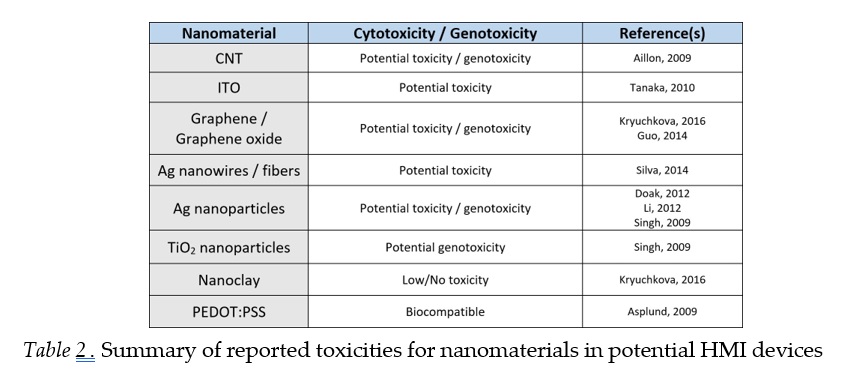

In assessing the safety of a particular design or product, aircraft certification system safety methodologies focus on the severity and probability of the hazard being addressed. In the case of nanomaterials for aircraft cockpit HMI, the high severity of cytotoxic / genotoxic effects of nanomaterial exposure due to possible effects on mortality would require that the probability of occurrence of the hazard be “Improbable” in order to be acceptable. The nanomaterials of concern in this study are thus those that are indicated with reports of toxicity as shown in Table 2.

Generally, many studies seem to indicate that Carbon-based nanomaterials used in structural applications have a low exposure potential since they are mostly used as composite components and the nanomaterial is embedded with the matrix (Aschberger et al., 2011). A review of various studies on MWCNT potential for release from composites indicate that mechanical forces such as those during normal operations would typically release the CNT embedded with the matrix particle, and that release of the CNT in its own form is extremely improbable through such modes. The primary condition which had a potential for release of free CNTs was through weathering – erosion following degradation by hydrolysis/oxidation (Harper, 2015). However, it is deemed that the hazard can be mitigated by an appropriate coating on the assembly to prevent or slow hydrolysis.

The probability of exposure to ITO, Graphene / Graphene Oxide, and even CNT in touch-screen applications are also generally low, primarily due to current designs where these transparent conductive oxides are used under a Polyethylene Terephthalate (PET) top-sheet. On such devices, the physical contact with users is through the PET surface which then transmits necessary deformations (e.g. pressing motions) to the layer below. Wear studies of the ITO/PET assembly indicate that the PET is extremely robust and that the transparent oxide layer would wear first with the PET layer being intact (Cairns, Crawford, & Chernefsky, 2001). Hence as long as future devices ensure a similar protective layer, the hazards from these transparent conductive oxide materials in touch-screens would also be well mitigated.

In general, nanomaterials for textiles are supposedly engineered to ensure that they stay in the textile for long periods of time. However, studies indicate that the release of engineered nanomaterials such as TiO2 or Ag nanoparticles could occur through mechanical abrasion when in direct contact with the skin, or degradation and erosion by washing and cleaning of the material (Som, Wick, Krug, & Nowack, 2011; Gottschalk & Nowack, 2011). Such studies suggest that the hazards from the use of nanomaterials in fabrics for seat covers, and as embedded devices in clothing for flight controls or display interaction could be mitigated with adequate consideration to the entire lifecycle of the product to include features such as a hydrophobic layer to prevent degradation during cleaning, or direct contact with perspiration.

Conclusions – overall material safety outlook

Overall, the outlook for the integration of nanomaterials in future enhancements in human-machine interfaces indicates that, while hazards exist from the potential cytotoxicity and genotoxicity of such materials, the residual risk to aircrew is low if key mitigation requirements for materials safety are considered in the device design. This initial study indicates that for the forseeable future, risks can be mitigated by ensuring appropriate segregation of the nanomaterial or bulk material embedded with nanomaterials to prevent mechanical abrasion, hydrolysis or oxidation. In addition, the operational lifecycle of the separation medium must be duly considered to ensure that it is robust even after repeated use within the useful life of the product to prevent the direct exposure of nanomaterials to the end-users. With such considerations in place, the aircrew should be at ease that the risks are duly mitigated. However, while this study aims to reduce the uncertainty on the safety of the use of nanomaterials for aircrews, it has not reviewed areas related to the full lifecycle of such products, including safety during manufacturing, waste disposal, or recycling. In addition, it has not considered how such materials could aggravate existing safety considerations to aircrew such as survivability from post-crash fires. While nanomaterials hold great promise for the industry, the new functional hazards introduced by nanomaterials must be well understood, and a level of certainty must be obtained on the risks to personnel before such technologies would be accepted by the industry.

References

- Advanced nanomaterials for aerospace applications. (2014). Pan Standford Publishing.

- Aillon, K. L., Xie, Y., El-Gendy, N., Berkland, C. J., & Forrest, M. L. (2009). Effects of nanomaterial physicochemical properties on in vivo toxicity. Adv Drug Deliv Rev, 61 (6), 457-66.

- Arbuckle, P. D., Abbott, K. H., Abbot, T. S., & Schutte, P. C. (1998, September 13-17). Future flight decks.

- Arepalli, S., & Moloney, P. (2015). Engineered nanomaterials in aerospace. MRS Bulletin, 40 (10), 804-811.

- Aschberger, K., Micheletti, C., Sokull-Kluttgen, B., & Christensen, F. M. (2011). Analysis of currently available data for characterising the risk of engineered nanomaterials to the environment and human health–lessons learned from four case studies. Environ Int, 37 (6), 1143-56.

- Asmatulu, R. (2013). Nanotechnology safety. Burlington, MA. USA.: Elsevier Science and technology.

- Asplund, M., Thaning, E., Lundberg, J., Sandberg-Nordqvist, A. C., Kostyszyn, B., In- ganas, O., & von Holst, H. (2009). Toxicity evaluation of pedot/biomolecular com- posites intended for neural communication electrodes. Biomed Mater , 4 (4), 045009.

- Barbé, J., Mollard, R., & Wolff, M. (2014). Ergonomic approaches to integrate touch screen in future aircraft cockpits. Journal Européen des Systèmes Automatisés, 48 (4-6), 303- 318.

- Boyes, W. K., Chen, R., Chen, C., & Yokel, R. A. (2012). The neurotoxic potential of engineered nanomaterials. Neurotoxicology, 33 (4), 902-10.

- Cahill, J., McDonald, N., Morrison, R., & Lynch, D. (2016). The operational validation of new cockpit technologies supporting all conditions operations: a case study. Cognition, Technology Work, 18 (3), 479-509.

- Cairns, D. R., Crawford, G. P., & Chernefsky, A. F. (2001). Wear resistance of indium tin oxide coatings on polyethylene terephthalate substrates for touchscreen applications. SID 01 Digest, 4.

- Cardin, S., Vexo, F., & Thalmann, D. (2006). Vibro-tactile interface for enhancing abilities during long term flight. Ecole Polytechnique Federale de Lausanne.

- Chang, J., Dommer, M., Chang, C., & Lin, L. (2012). Piezoelectric nanofibers for energy scavenging applications. Nano Energy, 1 (3), 356-371.

- Comerford, D., & Johnson, W. W. (2007). Potential capabilities in a future augmented cockpit. Ergonomics in Design, 8-13.

- Coni, P., & Rouzes, S. (2014, 05 Dec 2013). Multitouch tactile device with multi frequency and barycentric capacitive detection (Nos. 14/098,407).

- Doak, S. H., & Pfuhler, S. (2012). Nanotoxicology. preface. Mutat Res, 745 (1-2), 1-3.

- Franco, A., Hansen, S. F., Olsen, S. I., & Butti, L. (2007). Limits and prospects of the “incremental approach” and the european legislation on the management of risks related to nanomaterials. Regul Toxicol Pharmacol, 48 (2), 171-83.

- Gottschalk, F., & Nowack, B. (2011). The release of engineered nanomaterials to the environment. J Environ Monit, 13 (5), 1145-55.

- Grunhagen, W. v., Mullhauser, M., Abildgaard, M., & Lantzsch, R. (2010, September 7-9). Active inceptors in fhs for pilot assistance systems.

- Guo, X., & Mei, N. (2014). Assessment of the toxic potential of graphene family nanomaterials. J Food Drug Anal, 22 (1), 105-15.

- Haydon, B. (2012). Nanomaterials and their applications in textiles – standards domestic standardization for canadian manufacturers and importers and international stan- dardization developments (Tech. Rep.). Canadian Standards Association.

- Ionut, C. (2011). Ergonomic design of aircraft cockpit. Journal of Industrial Design and Engineering Graphics, 6 (1), 4.

- Jo, G., Choe, M., Lee, S., Park, W., Kahng, Y. H., & Lee, T. (2012). The application of graphene as electrodes in electrical and optical devices. Nanotechnology, 23 (11), 112001.

- Kim, W., Oh, H., Kwak, Y., Park, K., Ju, B. K., & Kim, K. (2015). Development of a carbon nanotube-based touchscreen capable of multi-touch and multi-force sensing. Sensors (Basel), 15 (11), 28732-41.

- Kryuchkova, M., Danilushkina, A., Lvov, Y., & Fakhrullin, R. (2016). Evaluation of toxicity of nanoclays and graphene oxide in vivo: a paramecium caudatum study. Environ. Sci.: Nano, 3 (2), 442-452.

- Li, Y., Chen, D. H., Yan, J., Chen, Y., Mittelstaedt, R. A., Zhang, Y., . . . Chen, T. (2012). Genotoxicity of silver nanoparticles evaluated using the ames test and in vitro micronucleus assay. Mutat Res, 745 (1-2), 4-10.

- Loeffler, J., Sutter, U., Jourdain, E., & Kristiansen, S. (2006). Nanomaterial roadmap 2015, roadmap report concerning the use of nanomaterials in the aeronautics sector (Tech. Rep.). Steinbeis-Europa-Zentrum.

- Lowry, G., & Casman, E. (2009). Nanomaterial transport, transformation, and fate in the environment. In L. Igor & J. Steevens (Eds.), Nanomaterials: Risks and benefits (p. 129-141). Dordrecth, Netherlands: Springer.

- Lubianez, R. (2011, October 23-26). High performance flexible transparent conductive film. Lynch, I., & Elder, A. (2009). Disposition of nanoparticles as a function of their interactions with biomolecules. In L. Igor & J. Steevens (Eds.), Nanomaterials: Risks and benefits (p. 40-50). Dordrecth, Netherlands: Springer.

- Nisha, M. S., & Singh, D. (2015). Manufacturing of smart nanomaterials for structural health monitoring (shm) in aerospace application using cnt and cnf. Journal of Nano Research, 37 , 42-50.

- Savolainen, K., Pylkkänen, L., Norppa, H., Falck, G., Lindberg, H., Tuomi, T., . . . Seipen- busch, M. (2010). Nanotechnologies, engineered nanomaterials and occupational health and safety – a review. Safety Science, 48 (8), 957-963.

- Singh, N., Manshian, B., Jenkins, G. J., Griffiths, S. M., Williams, P. M., Maffeis, T. G., . . . Doak, S. H. (2009). Nanogenotoxicology: the dna damaging potential of engineered nanomaterials. Biomaterials, 30 (23-24), 3891-914.

- Som, C., Wick, P., Krug, H., & Nowack, B. (2011). Environmental and health effects of nanomaterials in nanotextiles and facade coatings. Environ Int, 37 (6), 1131-42.

- Stanton, N. A., Harris, D., & Starr, A. (2016). The future flight deck: Modelling dual, single and distributed crewing options. Appl Ergon, 53 Pt B, 331-42.

- Stoddard, R. J., Steger, A. L., Blakney, A. K., & Woodrow, K. A. (2016). In pursuit of functional electrospun materials for clinical applications in humans. Future Medicine. Tanaka, A., Hirata, M., Kiyohara, Y., Nakano, M., Omae, K., Shiratani, M., & Koga, K. (2010). Review of pulmonary toxicity of indium compounds to animals and humans.

- Thin Solid Films, 518 (11), 2934-2936.

- Vaia, R. A., George, T., Islam, M. S., & Dutta, A. (2012). Nanomaterials and future aerospace technologies: opportunities and challenges. In Micro- and nanotechnology sensors, systems, and applications iv (Vol. 8373, p. 837324).

- Wu, J., Liu, W., Xue, C., Zhou, S., Lan, F., Bi, L., . . . Zeng, F. D. (2009). Toxicity and penetration of tio2 nanoparticles in hairless mice and porcine skin after subchronic dermal exposure. Toxicol Lett, 191 (1), 1-8.

- Xu, S., Shi, Y., & Kim, S.-G. (2006). Fabrication and mechanical property of nano piezo- electric fibres. Nanotechnology, 17 (17), 4497-4501.

- Yokel, R. A., & MacPhail, R. (2011). Engineered nanomaterials: exposures, hazards, and risk prevention. Journal of Occupational Medicine and Toxicology, 6 , 7.

- Zhang, L. W., & Monteiro-Riviere, N. A. (2009). Mechanisms of quantum dot nanoparticle cellular uptake. Toxicol Sci, 110 (1), 138-55.