Exploring the use of TRIZ to define an innovation search-space for electric motors

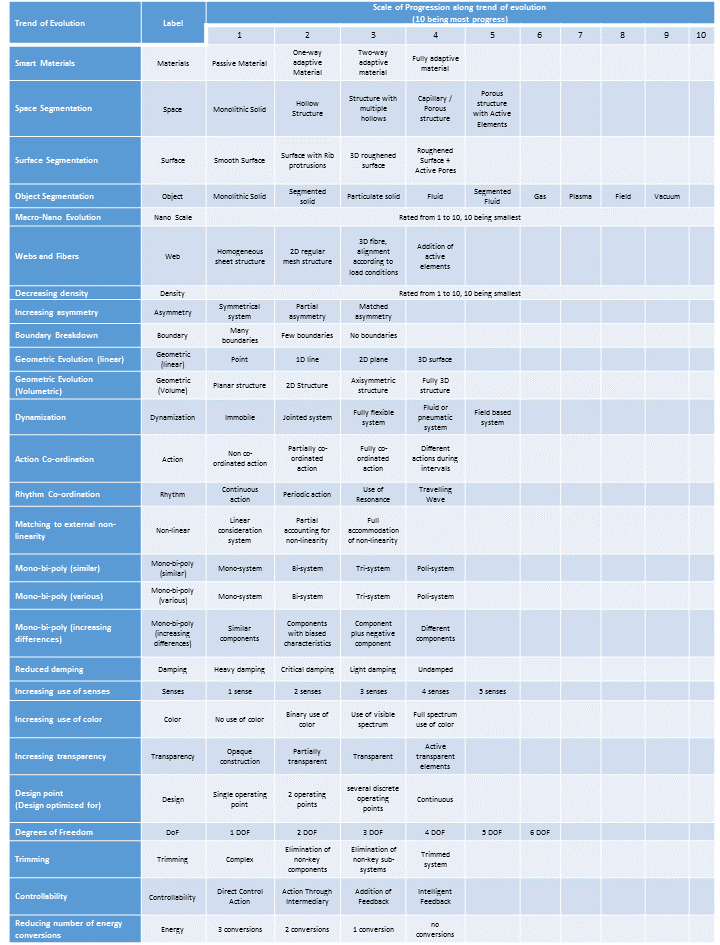

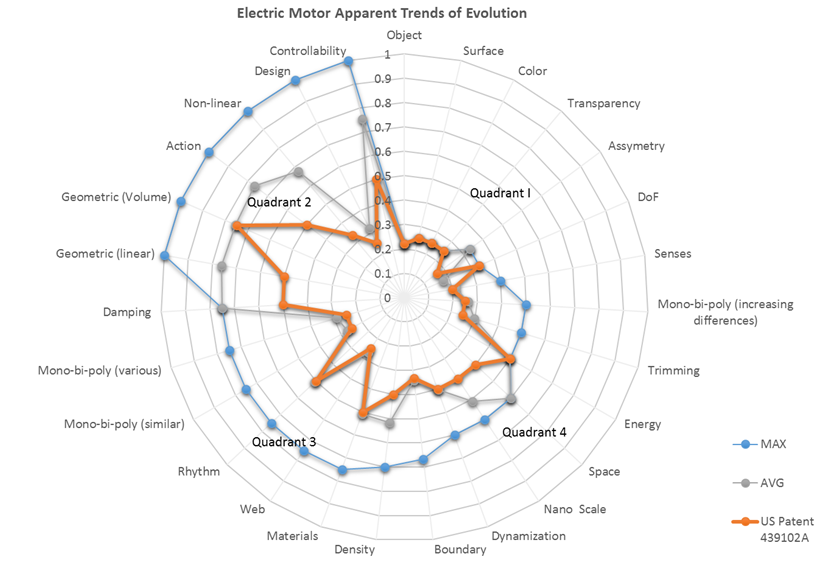

The use of the TRIZ method as a systematic means for innovation, especially in defining an innovation search space, has attracted industrial interest. While the TRIZ method for systematic innovation has been demonstrated on various products, there are no documented studies of the method being applied to electric motors. Electric motors are of great interest in the industry today due to their role in reducing global energy-related greenhouse gas emissions in the transportation sector. This paper explores applying the TRIZ method to electric motors to define an innovation search space. Specifically, it uses an extended definition of the TRIZ trends of evolution against a list of available patents from the last five years. In employing this method, this study has identified several potential Trends of Evolution in electric motors that could be considered underdeveloped and an opportunity for further innovation.

By Leo Jeoh